Somewhere over the rainbow

Strike while the iron is hot! Two blogs in two weeks; I’m running away with myself….

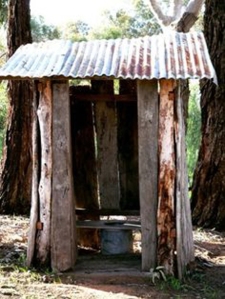

So as we are on the subject of our shiny new Colourbond corrugated steel roof, I thought I would expand a little bit on this very common material, and acknowledge its humble yet dignified place in the history of Australian buildings – notably as roof to the iconic Queenslander, but also as roof to churches, rotundas, terraces, as a building material for factory warehouses, shearing sheds, other farm sheds, water tanks, not to mention the great Australian Dunny.

No this is NOT our loo thankfully

The word corrugate originates from the latin corrugare, meaning ‘wrinkle’. It was patented in UK in April 1829 by Henry Robinson Palmer, “architect and engineer’” to the London Dock Company. From what I understand, the enormous strength of corrugated metal was discovered through a happy accident. A pliable sheet of iron was unintentionally crumpled in an early industrial revolution production line and Palmer acknowledged the increased resultant strength from the wrinkles. Ultimately, the corrugations enabled significantly larger spans to be achieved, (without the sheets sagging or collapsing).

corrugated iron curving machine (Powerhouse Museum)

In the mid 1800’s Queen Elizabeth’s husband, the visionary Prince Albert, ordered a corrugated iron ballroom for the Balmoral Estate in Scotland. It still stands, (now used as a joiner’s workshop) and is possibly the oldest metal sheet building in existence.

Good enough for a king and queen – the corrugated iron ballroom, built for Victoria and Albert at Balmoral Estate

Great Britain exported corrugated steel to its colonial outposts (specifically Australia) from the 1850’s through to the first quarter of the twentieth century. It’s pretty extraordinary and ironic that we became Britain’s largest customer from the 1880, with huge quantities shipped from UK across the high seas to our shores…(Specifically as now we are the largest exporter of iron ore, digging it up and shipping it off to China and beyond). The sheets were popular as they were easily transportable and were used to make prefabricated structures in our expanding settlements.

Steel rusts. And so some clever alchemy was patented in the late 1830’s called galvanising. The steel was dipped in molten zinc, which was resistant to rust. Corrugated steel sheeting today can survive for 20+ years if the steel if protected by a layer of paint.

So in regard to our new roof, I went to Metroll – the factory in South Lismore that manufactured it and watched our very own sheets slide through the cold-rolling process to become corrugated. Is that an odd thing to do? Probably. But was kind of interesting to view as well.